Grease

The American Society for Testing and Materials (ASTM) defines lubricating grease as: "A solid to semifluid product of dispersion of a thickening agent in liquid lubricant. Other ingredients imparting special properties may be included" (ASTM D 288, Standard Definitions of Terms Relating to Petroleum).

Properties Of Grease

A true grease consists of an oil and/or other fluid lubricant that is mixed with a thickener, typically a soap, to form a solid or semisolid. Greases are usually shear-thinning or pseudo-plastic fluids, which means that the viscosity of the fluid is reduced under shear. After sufficient force to shear the grease has been applied, the viscosity drops and approaches that of the base lubricant, such as the mineral oil. This sudden drop in shear force means that grease is considered a plastic fluid, and the reduction of shear force with time makes it thixotropic. A few greases are rheotropic, meaning they become more viscous when worked. It is often applied using a grease gun, which applies the

Application Of Grease

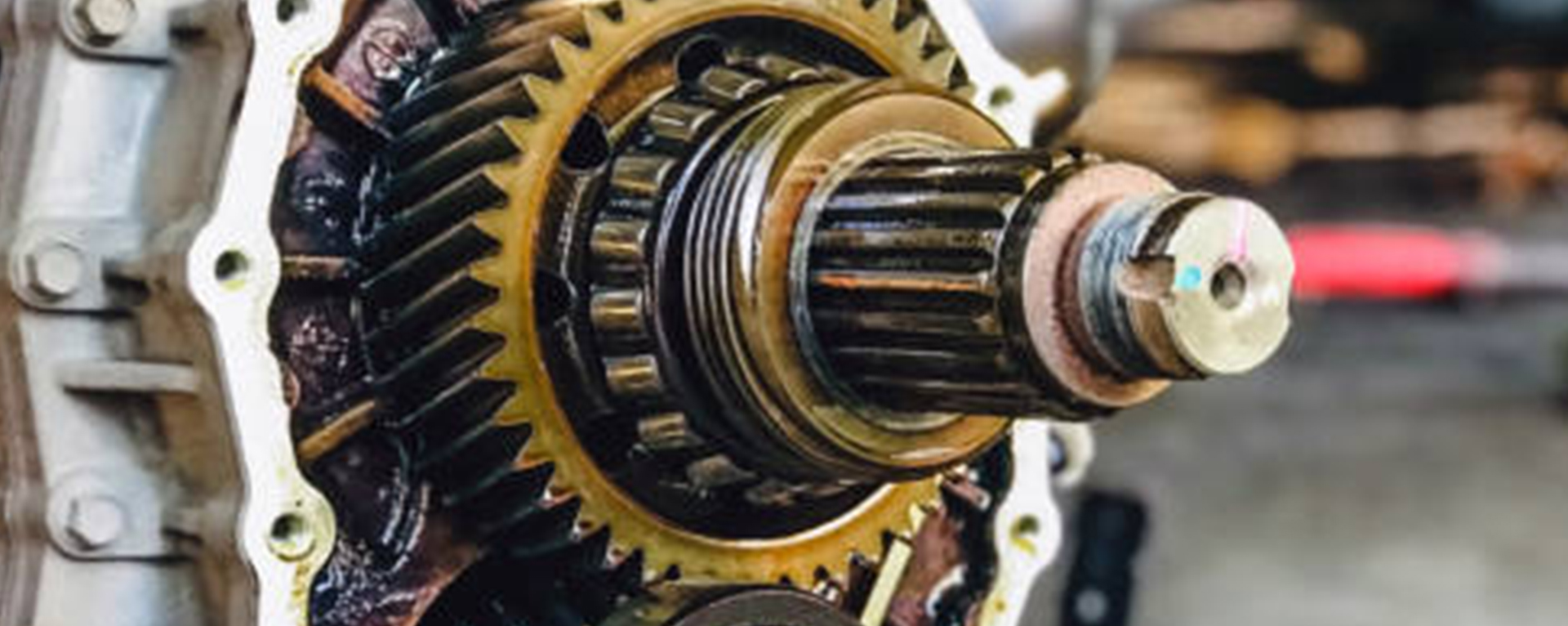

Grease and oil are not interchangeable. Grease is used when it is not practical or convenient to use oil. The lubricant choice for a specific application is determined by matching the machinery design and operating conditions with desired lubricant characteristics. Grease is generally used for:

Machinery that runs intermittently or is in storage for an extended period of time. Because grease remains in place, a lubricating film can instantly form.

Machinery that is not easily accessible for frequent lubrication. High-quality greases can lubricate isolated or relatively inaccessible components for extended periods of time without frequent replenishing. These greases are

About Grease Consistency

Consistency is a measurement of basic physical properties of grease indicating grease hardness, which can be adjusted by changing thickener content. Grease consistency has been classified by Japanese Industrial Standards (JIS) based on worked penetration measurements.